Pigging in the context of pipelines refers to the practice of using devices known as Pipeline Instrumentation Gauges “PIG” to perform various maintenance operations. This is done without stopping the flow of the product in the pipeline.

These operations include but are not limited to cleaning and inspecting the pipeline. Pigging has been used for many years to clean large diameter pipelines in the oil industry. Today, however, the use of smaller diameter pigging systems is now increasing in many continuous and batch process plants as plant operators search for increased efficiency and reduced costs. There are four main uses for pigs:

- Physical separation between different fluids flowing through the pipeline

- Internal cleaning of pipelines

- Inspection of the condition of pipeline walls (also known as an Inline Inspection (ILI) tool)

- Capturing and recording geometric information relating to pipelines (e.g., size, position).

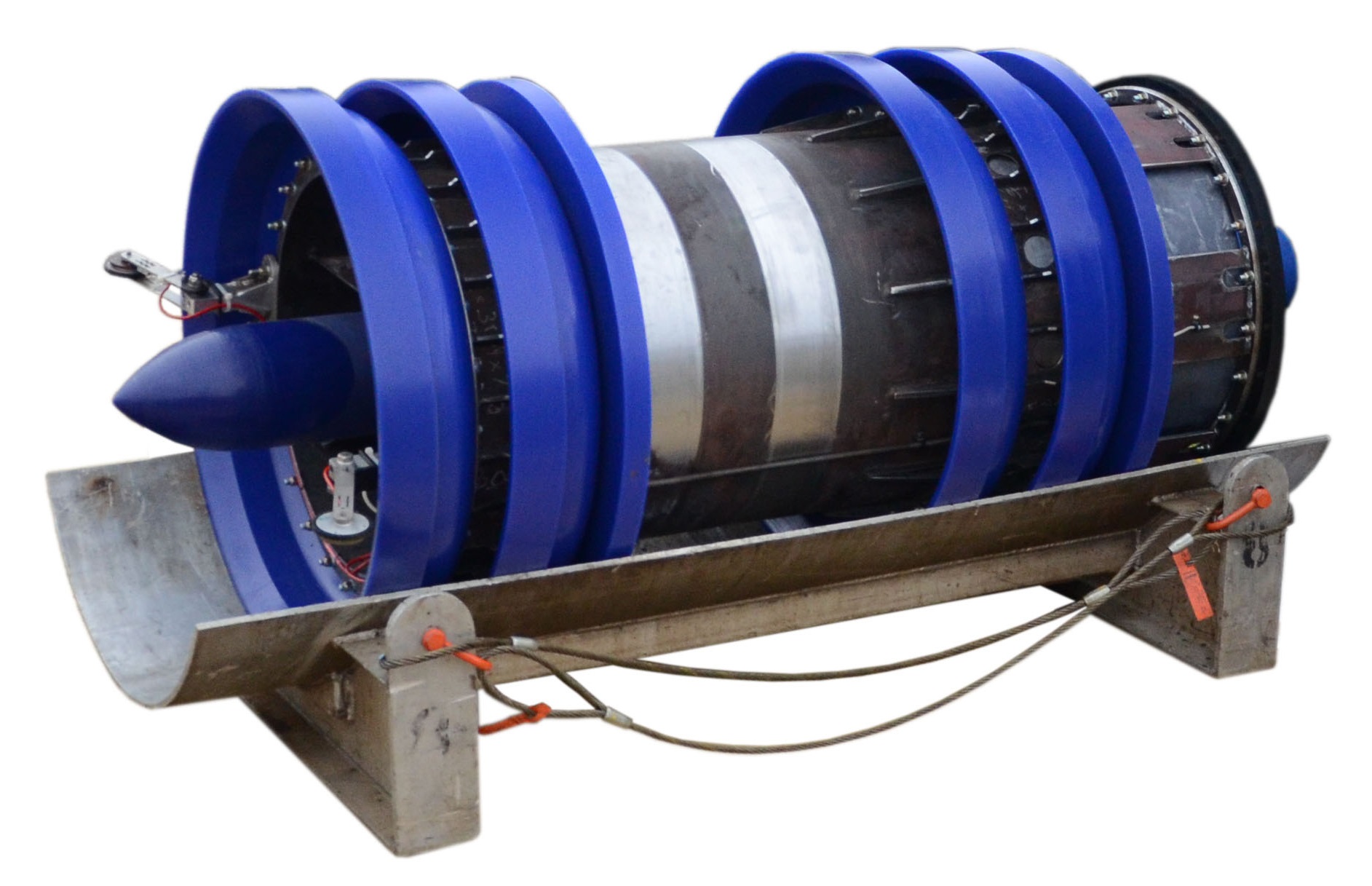

A typical Intelligent PIG device

PIG Types and Applications

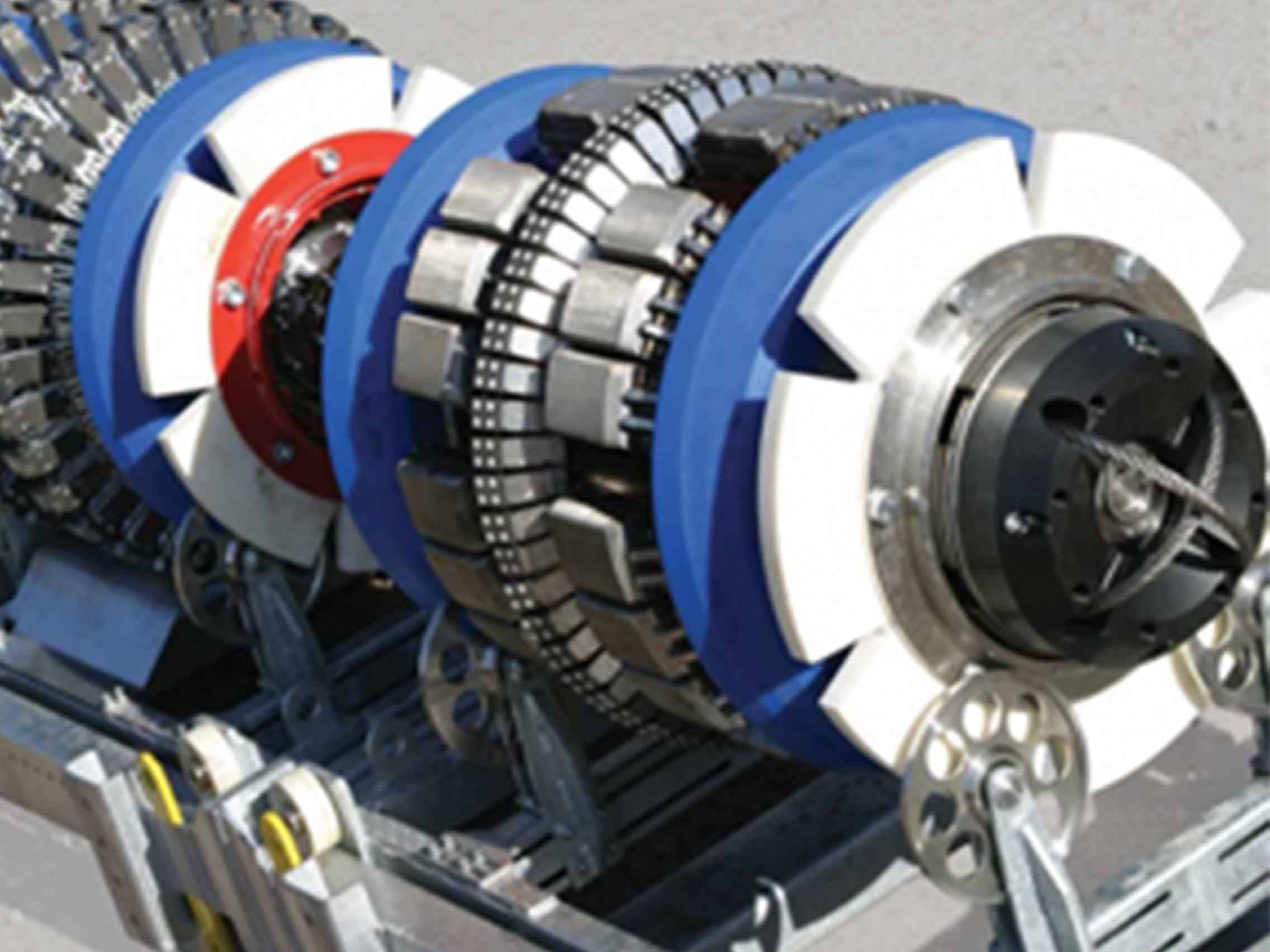

One of the most common and versatile type is the foam pig which is cut or poured out of an open cell polyurethane foam into the shape of a bullet and is driven through pipelines for many reasons like to prove the inner diameter of the line, clean it, dehydrate it, or dry it out. There are several types of pigs for cleaning in various densities. Some have tungsten studs or abrasive wire mesh on the outside to cut rust, scale, or paraffin wax deposits off the inside of the pipe. Other types are fully or criss-cross coated in urethane, or there are bare polyurethane foam pigs with a urethane coating just on the rear to seal and assist in driving the pig. There are also fully molded urethane pigs which are great for liquid removal or batching several different products in one line.

Inline inspection pigs use various methods for inspecting a pipeline. A sizing pig uses one (or more) notched round metal plates as gauges. The notches allow different parts of the plate to bend when a bore restriction is encountered. More complex systems exist for inspecting various aspects of the pipeline. Intelligent pigs are used to inspect the pipeline with sensors and record the data for later analysis. These pigs use technologies such as Magnetic Flux Leakage (MFL), Transverse Flux Leakage (TFI) and ultrasonic to inspect the pipeline. Intelligent pigs may also use calipers to measure the inside geometry of the pipeline.

A typical Cleaning PIG

A typical MFL PIG

MFL:

It is a tool to measure and identify the defections on the pipe (like corrosion, gouges and so on) through sensing a powerful axial magnetic filed which is generated to saturate the pipe wall. If there is any defection (thickness reduction) inner or outer of the pipe, the amount of saturated magnetic field will be reduced and it will be measured by Hall sensors mounted around the PIG’s body and then recorded in the memories of electronic boards for later analysis.

TFI:

To detect longitudinally oriented anomalies such as tunnel corrosion, longitudinal weld anomalies, it is utilized and induced a flux field in the circumferential direction. It also has a good performance in measuring some sort of crack-like anomalies. The usage of this tool is not used on its own and it usually pass through pipeline accompanying with MFL to achieve better accuracy in detecting anomalies in pipeline.

Calliper (EGP):

The Calliper employs to inspect all geometry deviations on a pipeline. It is very important to locate such deviation because:

- Variation in pipeline circular shape has negative effect on passing the product and increase consumption of power require for product transportation.

- Calliper can be considered as an survey of pipeline mapping and it will be used for future inspection data synchronization and fitness-for-purpose assessments.

UT:

The principle of ultrasound inspection is commonly known – using echo signals and registering reception time difference between them. In intelligent pigging application these high frequency radial signals are emitted by UT transducers perpendicularly to a pipe wall. These signals produce two major echoes – from inner surface and outer surface of a pipe wall. The anomalies are detected through the registered difference between time periods of receiving the echo signals from healthy pipe (calibration values) and pipe wall with metal loss or any in-homogeneity.

Iranian National MFL PIG

Iranian National TFI PIG

Iranian National Calliper (EGP) PIG

Supervisor of Iranian National Intelligent PIG Project

Since April 2015, Aras Intelligent PIG Research Group has started a collaboration with research and development department of National Iranian Gas Company (NIGC) as the supervisor of Iranian national intelligent PIG project. This project is one of the ten crucial national projects thay Iranian Oil ministry has focused on. Segal Tech company is the engineering and procurement party of the project which have to design, supply all equipment and integrate them to provide three types of intelligent PIG namely High Resolution MFL, High Resolution TFI and the Calliper. Each of these intelligent PIGs consists of several major subsystems such as electronic and mechanical, signal processing and software for displaying the pipeline defects. Aras Intelligent PIG Research Group closely monitor and control the progression of this national project, as well as provides technical consultations to Segal Tech. The project has accomplished its design, manufacturing, assembly and pull trough tests so far, and is in its final stage of approvals.

Project manager: Prof. Hamid D. Taghirad

Deputy manager: Dr. Mohammad A. Khosravi

Experts: Amir Mobarhani, Samim Khosravi, Ebrahim Abedloo, Amir Molaei

Consultants: Dr. Ahmad Reza Tahsiri, Dr. Mohammad Ali Nekouei, Prof. S. ALi A. Moosavian, Prof. Ali Ghaffari.

In this research group we enjoyed collaborating with NIGC research and development staff including, Dr. Pakseresht, H. Ponyad, Sh. Vakili Zandieh, and the technical team of Segal Pardazesh Engineering Co. , including Dr. M. Basiri, H. Khoshnood, M. Alaeizadeh, . . .

Sepideh Samavatian, Sara Khayamim

| Performance Movies: | |

| · | Pipeline Construction (9.1 M) |

| · | Cleaning Pig (8M) |

| · | Profile Pig (9M) |

| · | Odometer Pig (8.2M) |

| · | Magnetic Flux Leakage (MFL) (17M) |

| · | Ultrasonic Testing (UT) (16M) |

| · | Pipeline Defects (2.6M) |

| · | Pipeline Repair (6.5M) |